Categories:CNC/Lasers/Digital Cutters, CO2 Lasers

L6 300W CO2 Laser Machine

BrandsQuantum

- HIGH PRECISION

- LASER CUTTING

- MACHINE L6 SERIES

the wall of the plant. The specific distance should be changed according to the actual situation of the

customer, but it should not be less than the technical safety

distance.

shall be more than twice the weight of the equipment, and the flatness shall be ±3CM.

actual specifications of the purchased machines shall prevail.

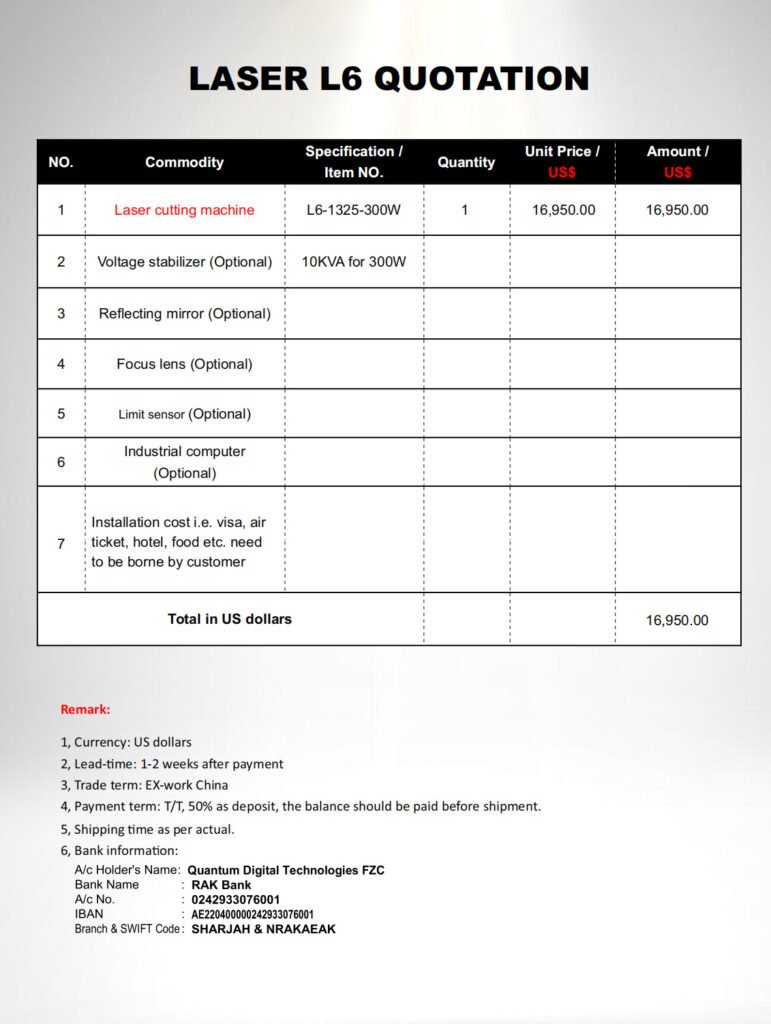

In case of voltage instability or power mismatch a voltage regulator or transformer may be used to meet

the above standards.

guarantee the carrying capacity of 1.5 times of the maximum installed power of the equipment

equipment

But cannot use mineral water, otherwise it will affect the service life of the laser;

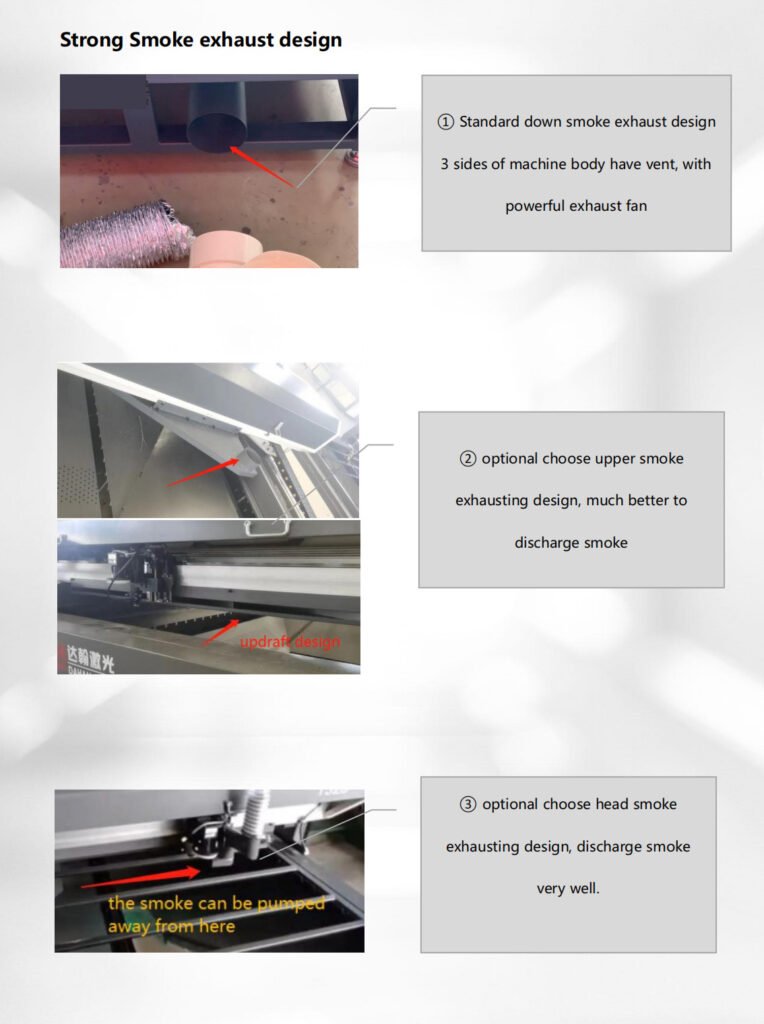

with less dust and rain protection.

dust and good ventilation, and the hot air generated by the chiller must be discharged out of the room.

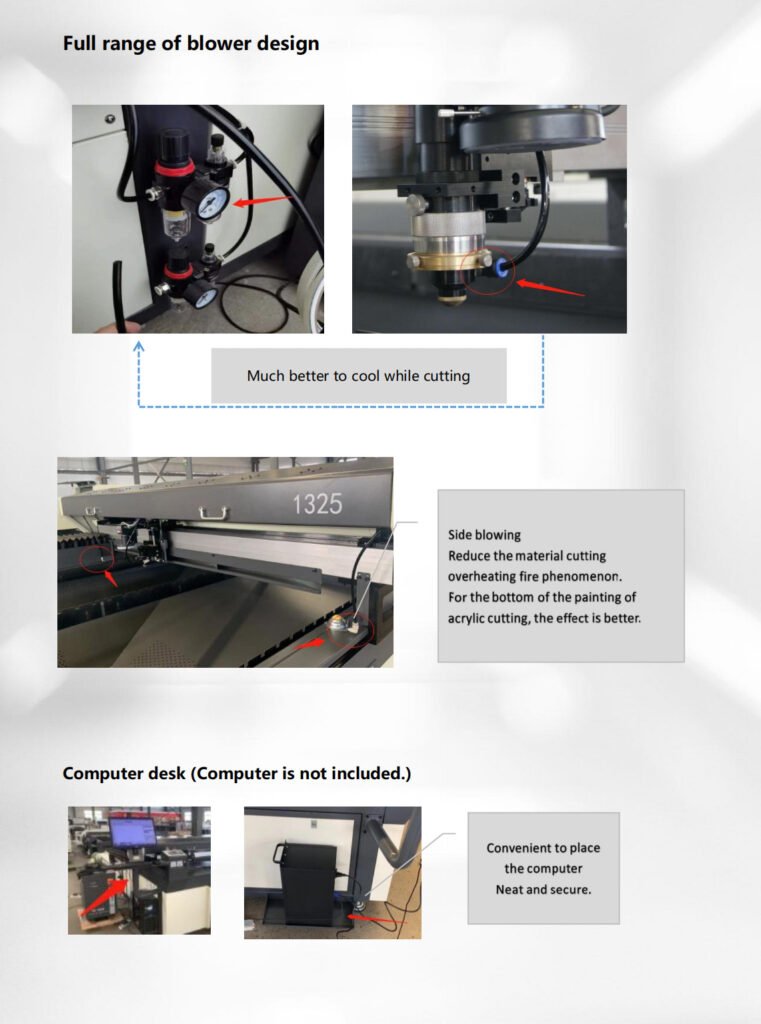

Make sure the air is clean and dry.

Air is from air compressor.

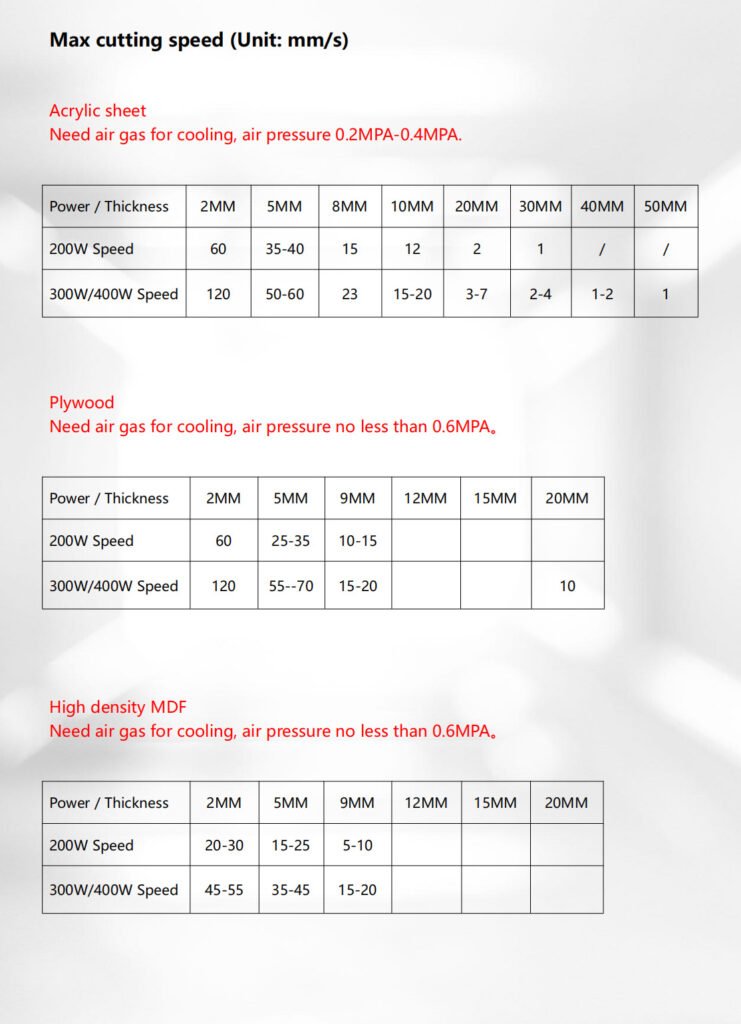

for cutting acrylic, just a small air pump is fine.

If for cutting wood/mdf/plywood, need higher pressure air, bigger than 0.8MPA is fine.